Infrared Temperature Sensors

RACELOGIC offer various sensor and monitoring kits to measure tyre temperatures and brake temperatures.

The Tyre Temperature Sensors (RLACS272) have been specifically designed to measure surface temperature of a tyre, providing invaluable information for chassis tuning and driver development.

The Brake Temperature Sensors (RLACS314) measures the highly transient surface temperature of a brake rotor, making it possible to acquire the time-based temperature distribution across a rotor's surface.

The data can be recorded using a VBOX Video HD2, which allows you to overlay the synchronised temperature data on the video or with VBOX Touch, which displays the temperature live on the 4.3” colour touchscreen.

Features

Temperature logging throughout the track sessions

Up to 16 temperature points per sensor

120° (tyre sensors only) and 60° field of view options

Pre-configured VBOX Video HD2 scene available

CAN Bus data output

Case Studies

2022 British GT4 championship winners, Steller Motorsport, use the VBOX Tyre Temperature Monitoring Sensors to increase tyre longevity and boost performance. Talking to Max Daymond, Technical Director at Steller Motorsport, we find out how the team got on using the VBOX TTMS kit and their plans for next season's racing.

Why use a Tyre Temperature Sensor?

Tyres provide their maximum level of grip when heated to within a certain temperature range. Finding out if your rubber is getting up to temperature, heating up evenly or over-heating due to lock-ups, imbalanced brakes, tyre pressures or poor setup is therefore a massive advantage.

By using our infrared tyre temperature monitoring kit, you can easily see how your tyres accumulate and dissipate heat during a lap, giving you a clear picture of what is happening.

When bundled with the VBOX Touch data logger (RLVBTTMS-M), you get a visual representation of the tyre temperature whilst on track.

The daylight readable 4.3" colour touchscreen displays the surface temperature of the tyres via individual heat maps, as well as the live temperature and maximum temperature values. Each sensor can measure up to 16 temperature points on an object with surface temperatures ranging from -20° C to 300° C.

The sensors can also be used with a VBOX Video HD2 data logger, which synchronises the recorded temperature data with the video and allows you to add it as a real-time graphic overlay to the video footage.

Why use a Brake Temperature Sensor?

A brake temperature sensor measures the highly transient surface temperature of a brake rotor at multiple points, making it possible to acquire the time-based temperature distribution across a rotor's surface. This helps you to evaluate and optimize the pad pressure distribution, pad selection, cooling efficiency, braking efficiency, and hot spot formation from thermoelastic instabilities.

Each sensor is capable of measuring temperature at 16, 8, and 4 points, at a sampling frequency of up to 100 Hz and an object temperature of between -20 to 1100˚C. All sensors are enclosed in a compact IP66 rated aluminium housing.

When bundled with the VBOX Touch data logger (RLVBBTMS), you can measure, log and monitor the surface temperature for all four brake disks on a daylight readable 4.3" colour display. The brake temperature monitoring app will show a heat map for each sensor, live temperature and maximum temperature values.

The brake temperature sensors can also be used with a VBOX Video HD2 data logger. The recorded temperature data is synchronised with the video and can be displayed as a real-time graphic overlay on the video footage.

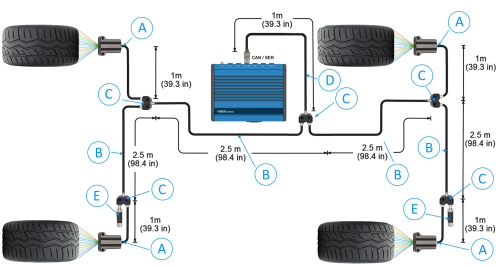

Connection to a VBOX Video HD2

The infrared temperature sensors need to be positioned directly opposite and central to each tyre surface. Two 3.2 mm holes are available on either side of each sensor for securely mounting them to the chassis.

After the sensor installation is complete, the LEMO connector from the infrared Tyre Temperature Monitoring loom must be plugged into the “CAN/SER” socket on the back of the VBOX HD2.

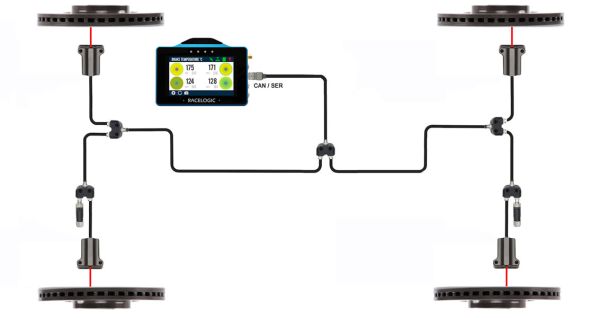

Connection to a VBOX Touch

The infrared temperature sensors need to be positioned opposite and across each brake disc's surface. Two 3.2 mm holes are available on either side of each sensor for securely mounting them to the chassis. Alternatively, 3M Dual Lock can be used, however it is advisable to tether them to the chassis as well.

After the sensor installation is complete, the LEMO connector from the temperature sensor loom must be plugged into a “CAN/SER” socket on the side of the VBOX Touch.

Technical Specifications

Weight: 20 g

Protection Rating: IP 66

Recommended Supply Voltage:

5 - 12 V

Supply Current: 30 mA

Weight: 20 g

Protection Rating: IP 66

Recommended Supply Voltage:

5 to 8 V

Supply Current: 30 mA

Measurement Range: -20 to 1100° C

Accuracy: <±2.0% FS

Uniformity: ±1.0% FS for -20° C < Tp < 85° C

Noise Equivalent Temperature Difference (NETD):

0.8° C at 32 Hz, ε = 0.85

Measurement Range: -20 to 300° C

Accuracy (Central 10 Channels, Nominal):

±1.0° C for 0° C < Tp < 50° C

±2.0° C for Tp < 0° C and Tp > 50° C

Accuracy (First & Last 3 Channels, Nominal):

±2.0° C for 0° C < Tp < 50° C

±3.0° C for Tp < 0° C and Tp > 50° C

Field of View, FOV:

120° x 15° (ultra-wide)

Number of Channels: 16

Thermal Time Constant: 2 ms

Effective Emissivity: 0.85

Spectral Range: 8 to 14 μm

Field of View, FOV: 60° x 8°

Number of Channels: 16

Thermal Time Constant: 2 ms

Effective Emissivity:

0.01 – 1.00 (default = 0.55)

Spectral Range: 8 to 14 μm